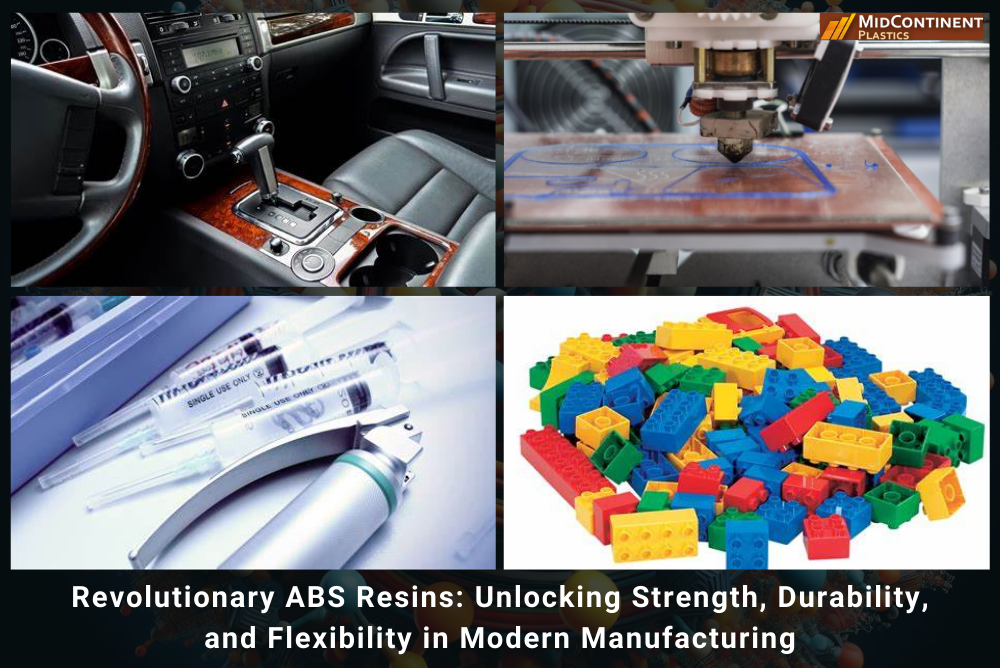

When it comes to manufacturing, engineers and designers are always on the lookout for materials that strike the perfect balance between strength, durability, and flexibility. One such material that has gained widespread popularity is ABS resin—short for Acrylonitrile Butadiene Styrene. This versatile thermoplastic has become a go-to choice across multiple industries due to its unique properties and wide range of applications. In this post, we’ll take a closer look at what makes ABS resins so special and why they continue to be a key player in modern manufacturing.

What Are ABS Resins?

ABS resins are a type of thermoplastic polymer made by combining three monomers: acrylonitrile, butadiene, and styrene. This blend gives the material a combination of toughness, rigidity, and impact resistance that few other plastics can match. As a copolymer, ABS is known for its stability and adaptability, making it ideal for use in everything from consumer products to industrial components. Its versatility has led to widespread adoption in fields like automotive, electronics, and healthcare.

Key Properties of ABS Resins

Understanding the properties of ABS resins can help you appreciate why they are so widely used. Here are some of the most notable characteristics:

- Excellent Impact Resistance: The butadiene component in ABS provides high impact strength, making it resistant to cracking or breaking under sudden force. This makes it ideal for parts that may experience shocks or collisions.

- Good Flexibility and Ductility: While rigid, ABS is also somewhat flexible, allowing it to bend without breaking. This property is especially useful in applications where some degree of movement or deformation is expected.

- Dimensional Stability: ABS maintains its shape and size even when exposed to temperature changes or humidity, ensuring long-term performance in various environments.

- High Tensile Strength: With strong tensile properties, ABS is suitable for structural components that need to support weight or withstand stress over time.

- Easy to Process and Paint: ABS is easy to mold, cut, and paint, which makes it a favorite among designers and manufacturers looking for both function and aesthetics.

Common Applications of ABS Resins

Due to their excellent balance of properties, ABS resins are used in a variety of industries. Some of the most common applications include:

- Automotive: Dashboards, door panels, bumpers, and other interior and exterior parts benefit from ABS’s durability and impact resistance.

- Electronics: Computer cases, TV enclosures, and appliance housings often use ABS for its insulation and heat resistance.

- Consumer Goods: Toys, kitchenware, and luggage are frequently made from ABS because of its strength, ease of molding, and aesthetic appeal.

- Construction: Pipes, fittings, and decorative elements are often made from ABS due to its chemical and weather resistance.

- Medical Devices: ABS is used in medical equipment and prosthetics thanks to its biocompatibility and ability to be sterilized easily.

As technology continues to evolve, the demand for reliable, high-performance materials like ABS resins is only going to grow. Whether you're an engineer, designer, or manufacturer, understanding the benefits of ABS can help you make informed decisions about your next project. If you're looking for high-quality ABS resins, consider reaching out to Mid Continent Plastics. They offer a wide range of options to suit different needs and volumes. Contact them today to learn more about how ABS can enhance your manufacturing process.

CNC lathe is a machine tool for machining metals and other materials, which controls the movement of the table and tools by a computer or other digital device to achieve high precision and efficiency. Compared with traditional lathes.

Structural characteristics of CNC vertical lathe:

CNC vertical lathe is a CNC vertical lathe whose main structure is base and single column type structure with table, fixed beam, square ram and single tool holder structure, which is an economic CNC vertical lathe with high rigidity and high cost performance. The casting process of CNC vertical lathe is large in volume and complex in structure, the amount of iron liquid poured is large, the cooling time of the casting is long, and casting defects such as shrinkage, shrinkage, pore, crack and substandard mechanical properties are easy to appear, and it is difficult to control the production process. The base, column and beam of CNC vertical lathe are made of high-strength cast iron with good shock absorption; the large span hardened guide rail has good wear resistance and long-lasting precision maintenance. Symmetrical box structure can carry heavy cutting with high torque. The ram adopts square structure, with good precision. Fixed cross beam, good rigidity and high precision. CNC vertical lathe single tool block structure, stable and reliable precision. Centralized machine operation panel â—‡Makes the operation more convenient and quick. It can process various internal and external cylindrical surfaces, conical surfaces, circular curved surfaces, etc. CNC vertical lathe is suitable for processing parts such as motor shells, large and medium-sized disk sets and covers. It is suitable for electromechanical, automobile, wind power, engineering machinery and other industries.

Cnc Vertical Lathes,Vertical Turning Lathe,Cnc Vertical Turret Lathe,Vertical Cnc Lathe Machine

Ningbo Yien Machinery Co., Ltd , https://www.yienmachinery.com

![<?echo $_SERVER['SERVER_NAME'];?>](/template/twentyseventeen/skin/images/header.jpg)