When it comes to manufacturing, engineers and designers are always on the lookout for materials that strike the perfect balance between strength, durability, and flexibility. One such material that has gained widespread popularity is ABS resin—short for Acrylonitrile Butadiene Styrene. This versatile thermoplastic has become a go-to choice across multiple industries due to its exceptional properties. In this article, we’ll take a closer look at what makes ABS resins so special, their key characteristics, and where they’re commonly used.

About ABS Resins

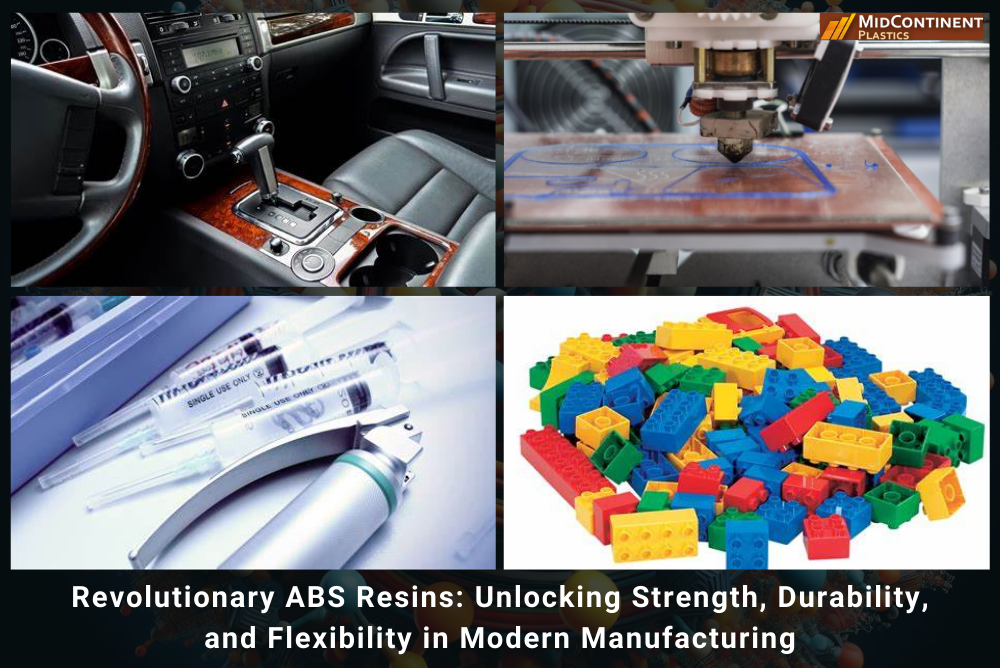

ABS resins are a type of thermoplastic polymer made by combining three different monomers: acrylonitrile, butadiene, and styrene. This unique blend gives ABS its remarkable combination of toughness, rigidity, and impact resistance. As a copolymer, ABS is known for its stability and adaptability, making it ideal for a wide range of applications. It's widely used in everything from automotive parts to consumer electronics and even medical devices.

Key Properties of ABS Resins

Understanding the properties of ABS can help you decide whether it’s the right material for your project. Here are some of its most notable features:

- Excellent Impact Resistance: The butadiene component in ABS gives it high impact strength, making it ideal for products that may be subjected to sudden forces or collisions.

- Good Ductility: ABS is flexible enough to be stretched or bent without breaking, which makes it suitable for applications requiring some degree of movement or deformation.

- Dimensional Stability: Even under varying temperatures and environmental conditions, ABS maintains its shape and size over time, ensuring long-term performance.

- High Tensile Strength: ABS can withstand significant tension without deforming, making it suitable for structural components and load-bearing applications.

- Easy to Process and Paint: ABS is compatible with various finishing techniques, including painting, printing, and electroplating, offering great design flexibility.

- Wide Range of Color and Surface Options: It can be easily colored and finished to meet aesthetic requirements, making it a favorite among product designers.

Common Applications of ABS Resins

Due to its versatility, ABS is used in a variety of industries. Here are some of the most common areas where it shines:

- Automotive Industry: ABS is widely used in both interior and exterior car parts, such as dashboards, door panels, bumpers, and grilles, thanks to its impact resistance and durability.

- Electronics and Appliances: From computer cases to TV enclosures, ABS is popular for its insulating properties and resistance to heat and chemicals.

- Consumer Goods: Toys, kitchenware, luggage, and cosmetic containers often use ABS because it combines strength, aesthetics, and ease of molding.

- Construction and Architecture: ABS is used in pipes, fittings, and decorative elements due to its resistance to weathering and chemicals.

- Medical Devices: Its biocompatibility and ability to be sterilized make it suitable for medical equipment, prosthetics, and diagnostic tools.

As technology continues to evolve, the demand for high-performance materials like ABS is only going to grow. With its excellent mechanical properties, ease of processing, and broad application range, ABS resins have become an essential part of modern manufacturing. Whether you're working on automotive components, electronic enclosures, or medical devices, ABS is a reliable and cost-effective solution. If you're looking for high-quality ABS resins in different quantities, consider partnering with Mid Continent Plastics. Their team can help you find the right material for your needs. Reach out today to discuss your next project and discover how ABS can bring your ideas to life.

Automatic CNC lathe than ordinary machine tools in what is better?

First, the processing accuracy is constantly improving. Because the automatic CNC lathe is installed through the intelligent program to process the operation, so that the accuracy of the gatekeeper will be more rigorous, so that the quality and quality of processed products will have a significant improvement. Therefore, the process of promoting this in the market to bring the customer's choice is also more trustworthy.

Second, the applicable processing application scenarios will become more and more extensive. With a more prominent level of fully automatic technology, then in the different processing application scenarios can be affirmed. Therefore, when comparing, the performance advantages in all aspects will be more and more diversified, and the choice brought to the customer will be more assured. Only through the comparison of processing application scenarios, the advantages will be more prominent.

Third, the processing efficiency continues to improve, can be repeatedly processed many times, to ensure that the quality in all aspects will be higher and higher. This is also the fully automatic CNC lathe in the design of all should go to understand the aspects. As in the process of comparing ordinary machine tools, it is found that the technical performance in all aspects will be different, and the choice for customers will be different, which can be seen in the analysis of the technical advantages and characteristics.

Cnc Lathes,Cnc Flat Bed Lathe,Heavy Duty Vertical Lathes,Cnc Flat Bed Lathe Machines

Ningbo Yien Machinery Co., Ltd , https://www.yienmachinery.com

![<?echo $_SERVER['SERVER_NAME'];?>](/template/twentyseventeen/skin/images/header.jpg)